|

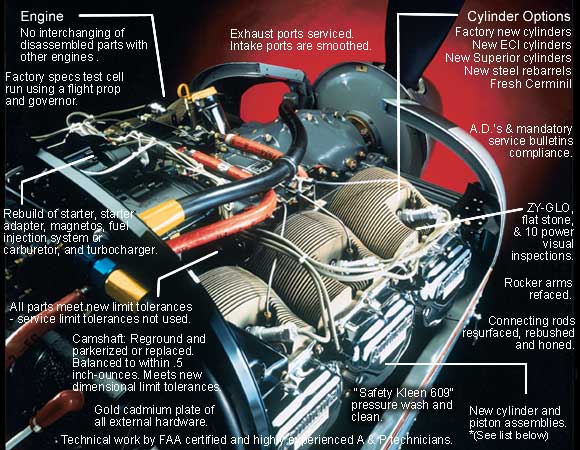

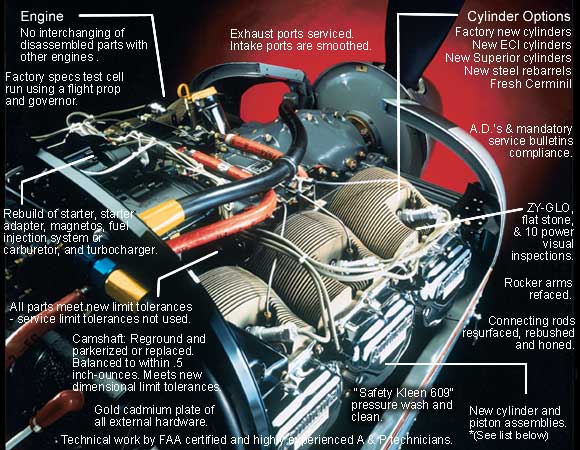

Engine

disassembled, all parts remain together, no interchanging

with other engines. |

|

Disassembly

report made. |

|

"Safety

Kleen 609" pressure wash and clean. |

|

All

oil galley plugs, caps and tubes removed and sludge

buildup removed. |

|

100%

replacement discardable items (pistons, valves,

etc.). |

|

Remaining

steel parts inspection using magnetic particle inspection,

ultrasound, micrometers, and 10 power visual. |

|

Aluminum

parts inspection using ZY-GLO, flat stone, and 10

power visual. |

|

External

serviceable parts painted or alodined to match the

engine. |

|

All

parts meet new limit tolerances - service limit

tolerances not used. |

|

A.D.’s

and mandatory service bulletins compliance. |

|

All

gears, castings, counterweights, and housings

replaced as required.

|

| |

NOTE:

All cylinders are brought to new limits by one

of the following options.

- Factory new cylinders

- Superior Millennium cylinders

- ECI new cylinders

- New steel cylinders

- Fresh channel chrome

- Fresh "Cerminil"

|

|

Cylinder

assemblies have NEW: Pistons, piston pins, piston

rings, intake valves, exhaust valves, intake and

exhaust seats, intake and exhaust guides, inner

and outer valve springs, valve keepers, roto coils,

oil control seals and rocker shafts. |

|

Exhaust

ports serviced. New exhaust studs installed as necessary.

Intake ports are smoothed as necessary - no metal

is removed. |

|

Rocker

arms refaced with new bushings and oil holes bored

to size. |

|

Connecting

rods resurfaced, rebushed, and honed to new tolerances.

Weight distribution checked and corrected, grind

areas shot peened. Rods checked for stretch and

alignment. All balanced to within 1 gram. All new:

Bushings, bolts, nuts, keys, and bearings. |

|

Crankshaft

balanced to within .5 inch-ounces and meets new

dimensional limit tolerances. If required, reground

and nitrated. All new counterweight bushings, pins,

plates, snap rings, plugs, and oil seal. |

|

Crankcase

oil galleys cleaned and pressure checked, all studs

torque checked and replaced as required, plugs installed.

Case repaired, resurfaced and line bored as necessary.

Complete assembly new: Nuts, lock washers, bearings,

seals and gaskets. |

|

Camshaft

reground and parkerized or replaced. |

|

All NEW hydraulic

plunger assemblies, oil pressure relief valve springs,

intake hoses, intake clamps, seals, gaskets, ignition

harness, spark plugs, and oil filter. |

|

Gold

cadmium plating of all external hardware. |

|

Engine

mounted oil coolers cleaned, pressure checked, inspected,

and repaired. |

|

Rebuild

of starter, starter adapter, magnetos, fuel injection

system or carburetor, and turbocharger. |

|

Factory

specs test cell run using a flight prop and governor.

A dynamometer is not used because it lacks thrust

load. |

|

All

technical work is performed by highly experienced

FAA certified A & P technicians. |

|

Six

(6) month, no hour limit, 100% warranty on parts

and labor. Thereafter prorated to TBO at 40 hours

per month including parts and labor. Warranty work

may be performed at other facilities after prior

approval. |

|

Ask about our THREE

(3) YEAR 100% parts

and labor warranty option. |

|

When shipping to your favorite FBO for installation, the engine will be carefully package in a real wooden crate (no cardboard boxes or other flimsy materials) with the same attention to detail found throughout our engine process. Shipping, when arranged by Western Skyways, will be insured for replacement cost and billed at actual shipping costs (not inflated). |